CellFusion is a company that specializes in providing innovative software solutions to optimize manufacturing processes. We offer cutting-edge MES technology to enhance productivity, improve quality control, and drive operational efficiency across various industries.

Absolutely! CellFusion solutions are highly customizable to meet the unique requirements of your manufacturing operations. Our team works closely with you, ensuring it aligns seamlessly with your existing processes and adapts to your evolving business needs.

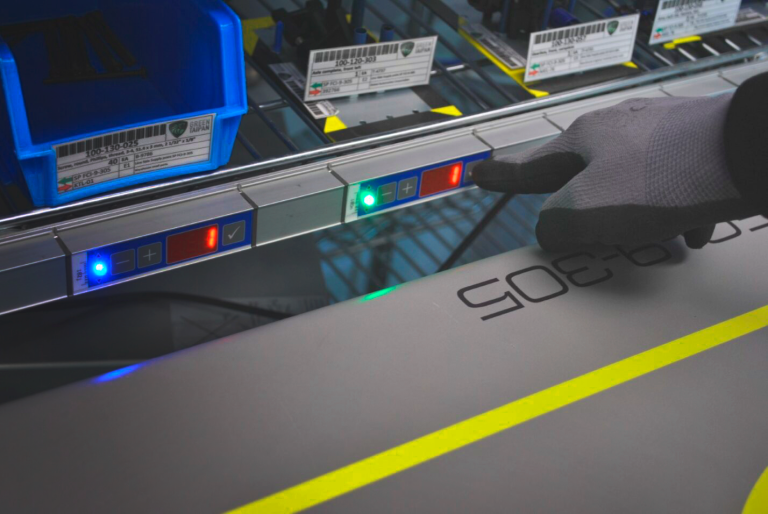

By implementing CellFusion, you can expect significant improvements in your production performance. The system provides real-time data, insights, and analytics, enabling data-driven decision-making, minimizing downtime, and optimizing resource utilization, leading to increased productivity and overall efficiency.

Yes, CellFusion is designed to integrate smoothly with a wide range of enterprise systems, such as ERP (Enterprise Resource Planning), PLM (Product Lifecycle Management), and more. This seamless integration ensures a holistic view of your manufacturing operations and enables effective data exchange between systems for better decision-making.

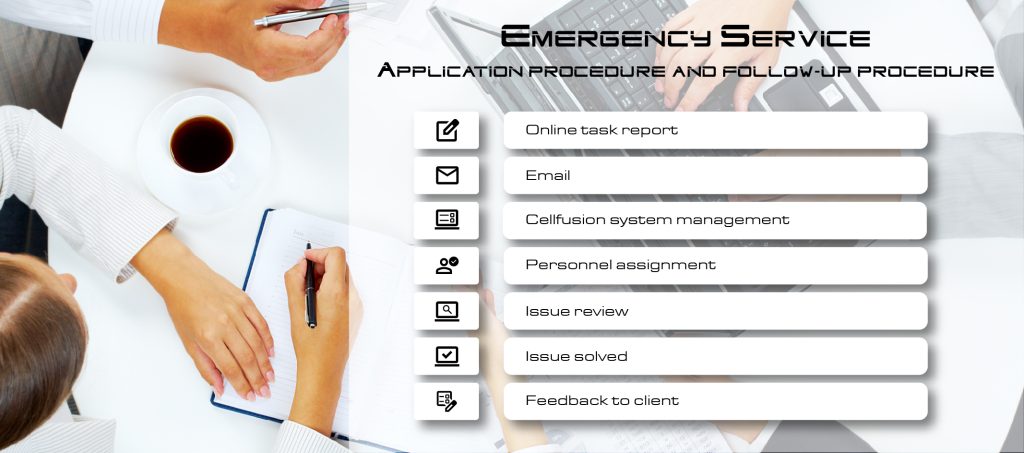

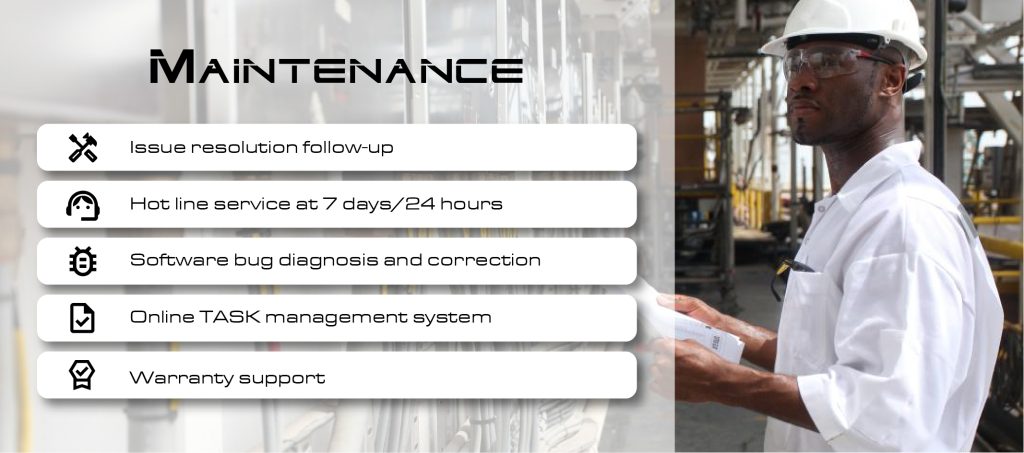

At CellFusion, we prioritize customer success and satisfaction. Our dedicated support team offers comprehensive assistance during the implementation phase, including training and onboarding for your team. Even after CellFusion is deployed, we provide ongoing support, updates, and maintenance to ensure the system continues to deliver optimal results for your business.